Space Actuation

Radiation Hardened Systems And Components

Honeywell has more than 50 years in experience on the analysis and mitigation of the effects of radiation on commercial and military systems. Our Radiation Effect Center of Excellence has test equipment that can perform both prompt gamma testing (flash x-ray) and high/low dose rate total dose testing (irradiator). Honeywell is home to the Trusted Foundry facility for radiation hardened microelectronics. We are the leading supplier of radiation hardened microelectronics design, fabrication, assembly, test, and delivery of these complex components. These combined capabilities make Honeywell the lowest risk supplier for any radiation hardened electronics equipment in the industry. It also keeps end item systems’ cost low, as there will not be layers of cost and fees associated with any radiation hardened microelectronic components.

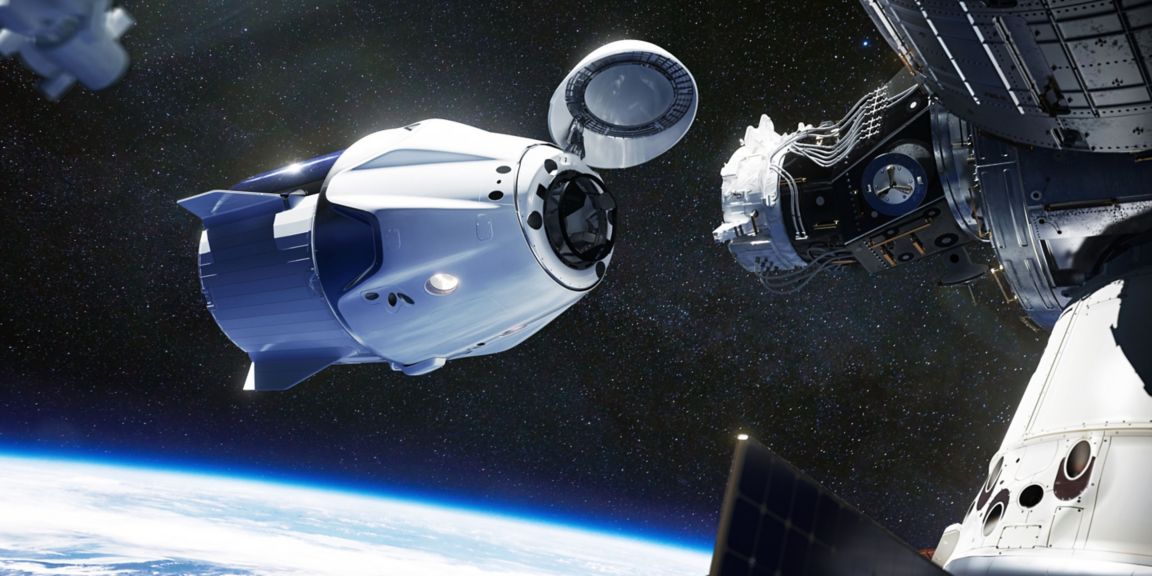

Docking System Actuation

NASA Docking mechanism actuators support berthing of US commercial cargo and US commercial crew spacecraft with the International Space Station (ISS) Our products perform capture, lock, separation, and mating of electrical connections between visiting Spacecraft and the ISS. All systems include redundancy features, Space rated motors and materials, and compact designs to achieve high reliability for manned space use.