-

Location

-

North America

-

Latin America

-

Asia Pacific

- |

- Sales & Service Partners

- |

-

Select Shopping Cart Account

Choose the account number for your parts ordering shopping cart. Your current cart will be saved when switching accounts.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Industries

Industries

-

Location

-

North America

-

Latin America

-

Asia Pacific

- |

- Sales & Service Partners

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- Blogs

- Honeywell Shapes the Future of Navigation at Minneapolis Hub

Your browser is not supported.

For the best experience, please access this site using the latest version of the following browsers:

By closing this window you acknowledge that your experience on this website may be degraded.

Honeywell Shapes the Future of Navigation at Minneapolis Hub

October 2, 2025

Honeywell Shapes the Future of Navigation at Minneapolis Hub

Honeywell’s Minneapolis hub pioneers navigation tech with MEMS, RLGs and IMUs for aerospace, defense and robotics—driving innovation and scaling production.

What You Will Learn in This Article

- How Honeywell’s Minneapolis hub is advancing inertial navigation technology through innovations like MEMS sensors and vertically integrated manufacturing processes.

- The strategic role of Minneapolis in Honeywell’s global navigation ecosystem, supporting applications across aerospace, defense, space, and emerging mobility platforms.

- Key production milestones and operational efficiencies that enable Honeywell to scale high-performance navigation devices to meet growing global demand.

The future of precision navigation is taking shape in a nondescript industrial building in Minneapolis. Here, more than 1,500 Honeywell Futureshapers are pushing the boundaries of guidance and control technology for aircraft, spacecraft, defense systems and advanced air mobility platforms.

“Our engineering and manufacturing teams are obsessed with making inertial navigation devices faster, smaller and cheaper, while also improving their performance,” said Andrew Krominga, Site Leader for the Minneapolis navigation hub.

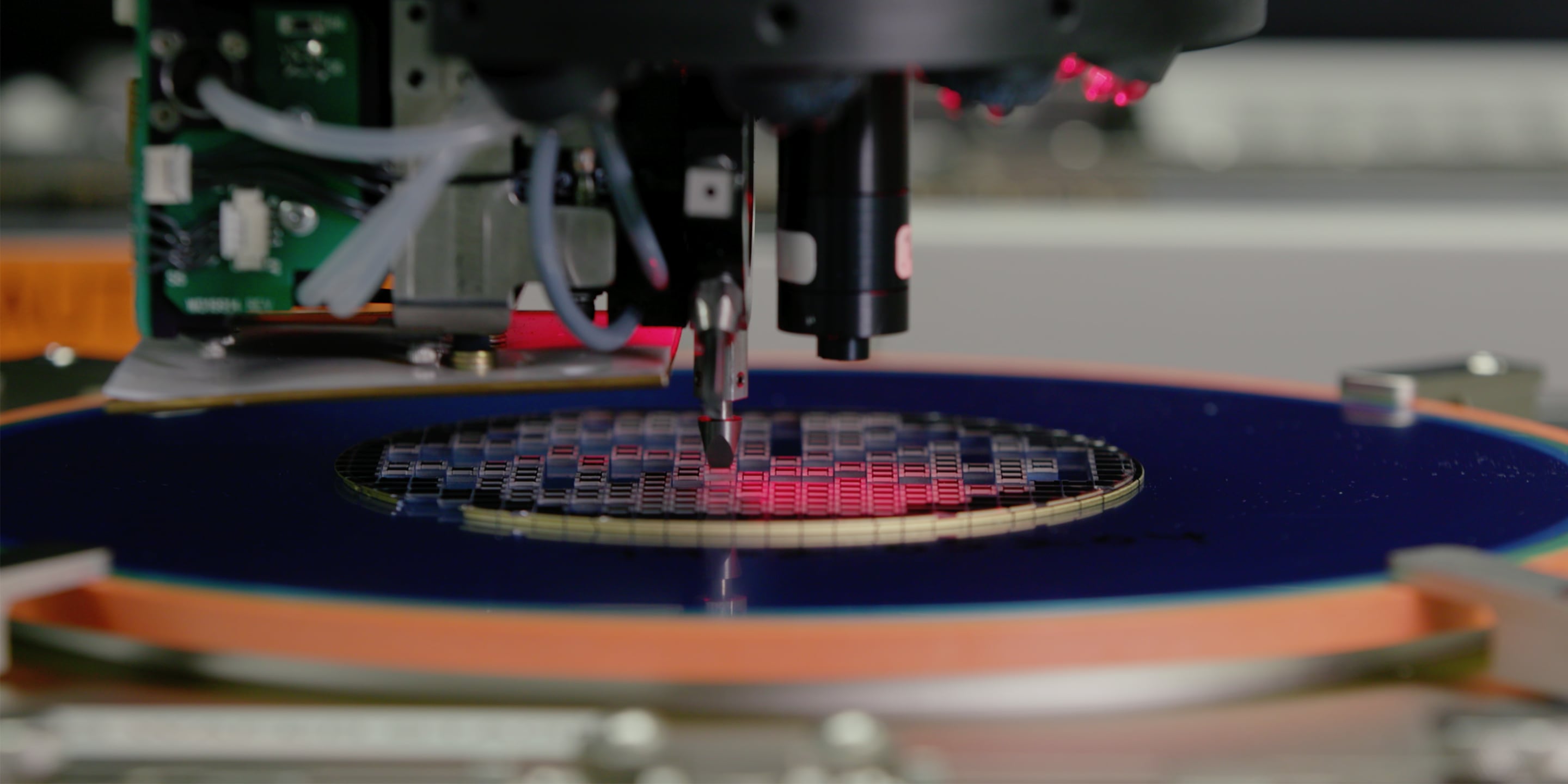

“Breakthrough technologies like micro-electro-mechanical systems (MEMS) are helping us achieve new levels of performance on tactical-grade devices with a much smaller form factor,” he said. “We’re also looking for ways to expand our use of MEMS in other products, and we envision these sensors will eventually replace the most widely used navigation device, the ring laser gyroscope (RLG).

Navigation and Control for Any Application

In addition to RLGs, the site develops and produces precision inertial measurement units (IMUs) used in Honeywell navigation and control products for commercial, defense, space and advanced air mobility (AAM) applications.

For example, airliners and business jets rely on inertial navigation systems (INS) to navigate safely and efficiently; ruggedized inertial devices guide military aircraft, helicopters, missiles and ground vehicles to mission success, even when GPS isn’t available; in space, Honeywell navigation technologies help control satellites and other space platforms; and uncrewed drones and next-generation air taxis need inertial devices to fly safely and efficiently.

Minneapolis employees work closely with other Honeywell sites, including the site in nearby Plymouth, Minnesota, which develops MEMS gyros and accelerometers for Honeywell navigation and control products. Honeywell manufactures conventional accelerometers in Redmond, Washington, and builds navigation systems incorporating Minneapolis products in Clearwater, Florida.

A History of Innovation

Honeywell pioneered technology that blends a Minneapolis-designed inertial navigation system (INS) with a global navigation satellite system (GNSS) more than 30 years ago, introducing the first LASEREF inertial reference system (IRS) in 1995.

Minneapolis employees are also bringing aerospace technology down to Earth by applying Honeywell IMU technologies to non-aerospace applications, such as oil and gas exploration and robotics, where precise positioning, stability and timing are critical.

The IRS combines GNSS and inertial inputs to calculate a vehicle's precise position, orientation and velocity. GNSS information corrects IMU drift, while the IMU maintains continuous navigation when satellite signals are blocked, delivering a “best of both worlds” navigation solution.

Producing High-Performance Devices at Scale

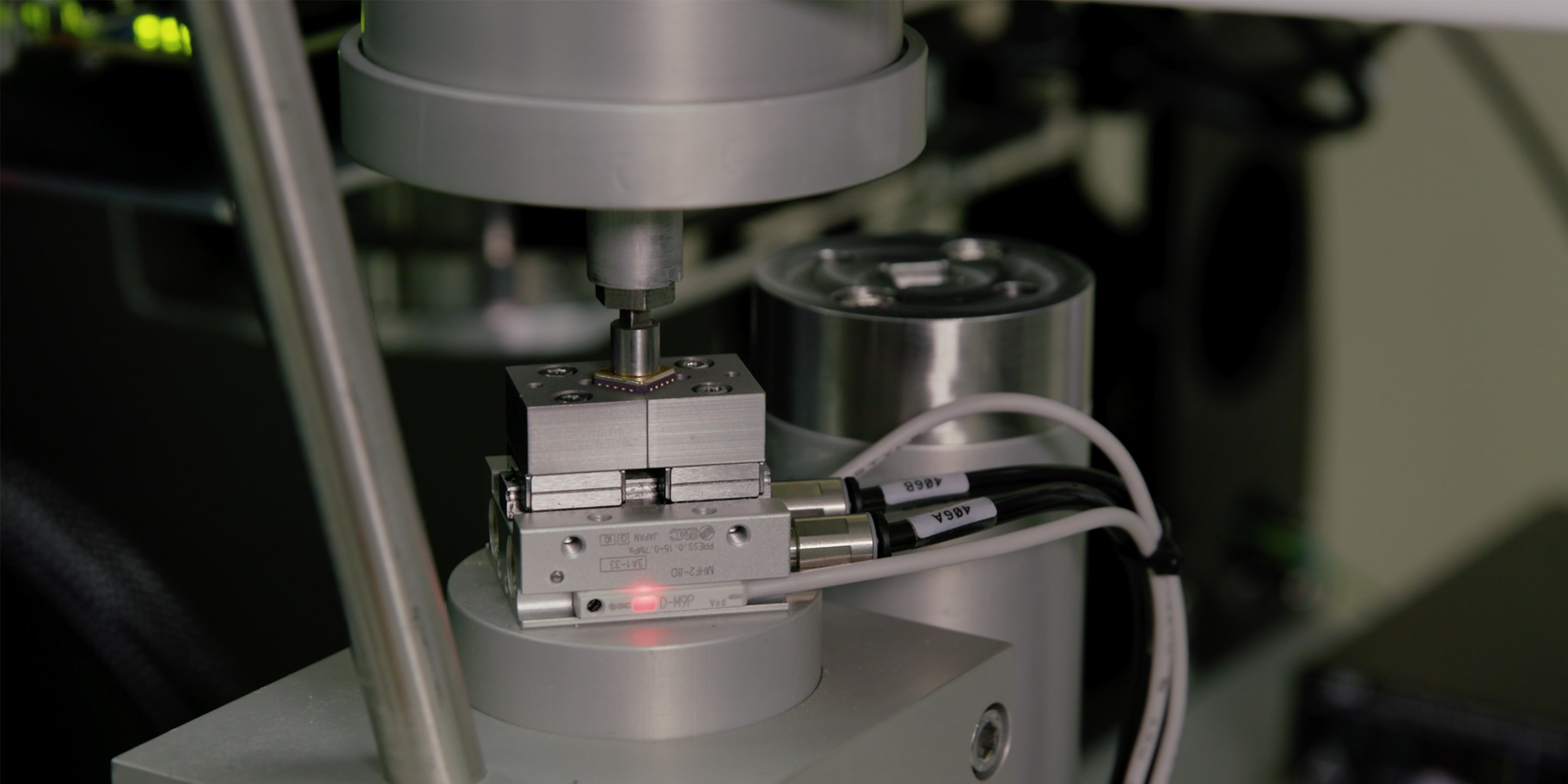

The Minneapolis site is Honeywell’s Inertial Navigation Center of Excellence, where R&D, manufacturing, final assembly and testing all occur under one roof.

"This vertical integration allows for rapid problem-solving and creative solutions, because people with diverse skill sets, backgrounds and experience work together in the same facility"

- Andrew Krominga, Site Leader for the Minneapolis Navigation Hub

"Honeywell designed the site to produce high-performance navigation devices at scale," he added. “We have increased production in recent years to meet growing demand for our products. We expect to produce approximately 42,000 RLGs and 120,000 IMUs in 2025, which is an increase from around 20,000 and 40,000 units, respectively, in 2007. In all, the site has produced well over 1 million IMUs and 800,000 RLGs to date and we’re continuing to add capacity.”

Process improvements, cycle time reductions and factory realignment have enabled the Minneapolis team to increase production without expanding the building. Krominga explained that manufacturing innovations and a commitment to the company-wide Honeywell Accelerator operating systems provide a playbook for growth and execution.

“Minneapolis employees are the not-so-secret factor in our success,” he said. “Their high level of engagement and strong connection to our products and the benefits they provide to our customers are key factors that make an enormous difference. Their dedication and commitment are instrumental in driving our navigation and control business forward and positioning us for success in the years ahead.”

Let's Connect!

The latest news in aerospace backed by expert insights

Sign up to receive the latest news about events, special offers and related topics via email and other forms of electronic communication.

Copyright © 2026 Honeywell International Inc.

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

Your documents are ready for you. Please click here to open.

Maximum File Size

Maximum Files Exceeded

There is an issue with invoices zip file download. Please go back and try again later. Thanks!

Maximum File Size

Maximum Files Exceeded

Your orders excel is ready for download. Please click here to download.

Maximum File Size

Maximum Files Exceeded

There is an issue with orders excel file download. Please go back and try again later. Thanks!